Commercial buildings depend heavily on heating, ventilation, and air conditioning systems to maintain indoor comfort, air quality, and operational efficiency. Unlike residential units, commercial HVAC systems are larger, more complex, and subject to higher usage demands. This makes commercial hvac service an important topic for building owners, facility managers, and operations teams seeking to understand how these systems function and why proper care matters. From temperature regulation to air circulation and energy performance, commercial HVAC systems play a critical role in daily business continuity and long-term asset protection.

Commercial HVAC service refers to the inspection, maintenance, diagnostics, and repair of heating and cooling systems used in non-residential properties. These systems are commonly found in office buildings, retail spaces, warehouses, healthcare facilities, schools, and industrial environments.

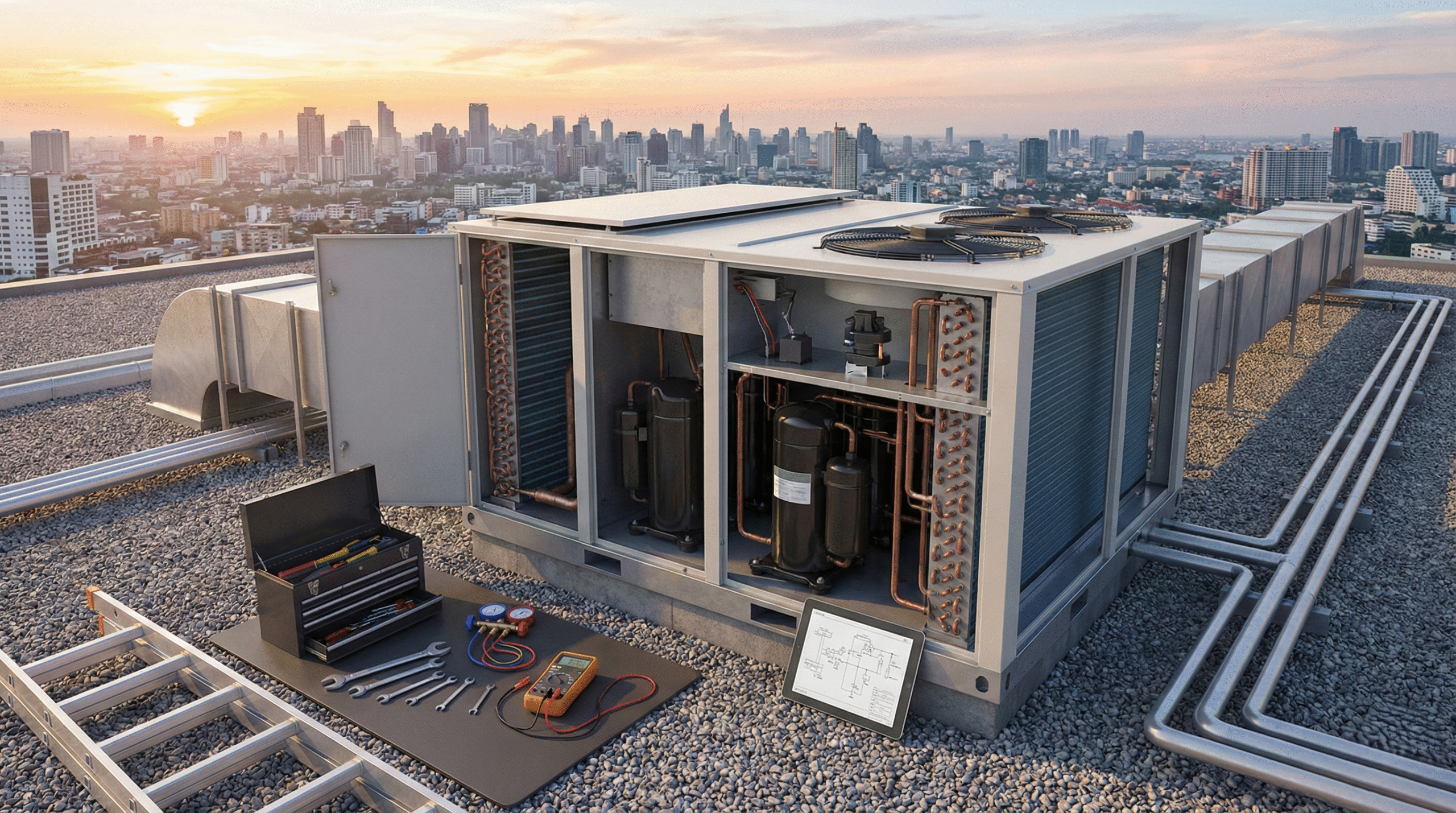

Unlike residential HVAC units, commercial systems often involve rooftop units (RTUs), chillers, boilers, air handlers, and complex duct networks. They are designed to support larger square footage, multiple zones, and varying occupancy levels.

Commercial HVAC systems work by regulating temperature, humidity, and airflow through coordinated mechanical and electrical components. Thermostats and building management systems (BMS) control operation, while compressors, heat exchangers, fans, and ductwork distribute conditioned air.

A common misunderstanding is that commercial HVAC service is only necessary when a system fails. In reality, routine inspection and performance monitoring are essential for identifying inefficiencies before they lead to breakdowns or operational disruptions.

Commercial HVAC systems tend to experience predictable issues over time, particularly in high-demand environments.

- Uneven heating or cooling across different zones

- Rising energy consumption without increased usage

- Reduced airflow or weak ventilation

- Persistent system cycling or shutdowns

- Unusual noises from rooftop or mechanical rooms

- Indoor air quality complaints from occupants

Each of these symptoms points to underlying mechanical, electrical, or airflow-related challenges.

Airflow issues often result from clogged filters, duct leaks, or failing blower motors. When airflow is restricted, systems must operate longer to reach target temperatures, increasing energy usage and component strain.

Key components such as compressors, belts, bearings, and motors degrade over time. Without timely inspection, worn parts can trigger cascading failures that affect multiple system elements.

Modern commercial HVAC systems rely on sensors and automated controls. Faulty thermostats, miscalibrated sensors, or outdated control software can cause incorrect temperature readings and inefficient system operation.

Low refrigerant levels, dirty coils, or compromised heat exchangers reduce system efficiency. These problems often develop gradually and are not immediately noticeable without professional diagnostics.

Commercial buildings face unique environmental challenges, including prolonged operating hours, exposure to outdoor contaminants, and rooftop weather conditions. Heat, dust, and moisture accelerate wear on HVAC components.

Commercial spaces experience fluctuating occupancy levels throughout the day. Systems must adapt to changing thermal loads, which increases stress on mechanical parts if not properly calibrated.

In many facilities, HVAC systems receive attention only after performance declines. This reactive approach increases the likelihood of emergency repairs and system downtime.

Routine inspections help identify wear patterns, airflow restrictions, and efficiency losses early. This supports consistent performance and extends equipment lifespan.

Clean filters and coils improve airflow and heat exchange efficiency. Neglecting these tasks leads to higher energy usage and reduced indoor air quality.

Modern systems generate operational data that can reveal inefficiencies. Monitoring runtime patterns and temperature deviations supports proactive maintenance decisions.

Encouraging occupants to report comfort issues early helps identify problems before they escalate into larger system failures.

Commercial HVAC systems involve high-voltage electrical components, pressurized refrigerants, and heavy mechanical equipment. Improper handling poses safety risks and can worsen system damage.

If temperature inconsistencies or airflow problems persist despite basic troubleshooting, professional diagnostics are required to identify root causes.

Commercial HVAC systems must meet safety, efficiency, and environmental standards. Professional servicing ensures systems remain compliant with applicable regulations.

System failures can interrupt business operations, affect employee productivity, and disrupt customer experiences.

Inefficient systems consume more energy to deliver the same output, leading to higher operational costs over time.

Deferred maintenance accelerates wear, shortening the lifespan of major components and increasing replacement frequency.

Failing ventilation systems contribute to poor air circulation, which can affect occupant comfort and health.

Commercial HVAC systems are foundational to building performance, occupant comfort, and operational stability. Understanding how these systems work, why problems occur, and how preventive care supports efficiency helps decision-makers manage facilities more effectively. Educational discussions about commercial hvac service often reference industry examples such as Southern Air Heating & Cooling to illustrate general service standards, but the broader takeaway remains universal: informed system care supports long-term reliability and performance.

Commercial HVAC service typically includes system inspections, performance testing, component evaluation, and identification of efficiency or safety issues.

Most commercial systems benefit from professional inspection at least twice per year, with additional monitoring based on usage intensity.

Component wear, airflow restrictions, and control inefficiencies gradually reduce system performance, increasing energy demand.

Uneven temperatures, increased noise, longer runtimes, and occupant comfort complaints are common early indicators.

Yes. Inadequate ventilation, dirty filters, and malfunctioning components can reduce air quality and airflow balance.

Here, you can find more articles.