Hot water is a basic necessity in modern households, supporting daily activities such as bathing, cooking, cleaning, and laundry. When a water heater reaches the end of its lifespan or begins to fail, homeowners often search for guidance on water heater installation service in Derry, NH to understand what the process involves and what factors influence long-term performance. This topic matters because improper installation or poor planning can lead to inefficiency, safety risks, and avoidable expenses. An educational understanding of how water heater installation works helps homeowners make informed decisions and avoid common pitfalls.

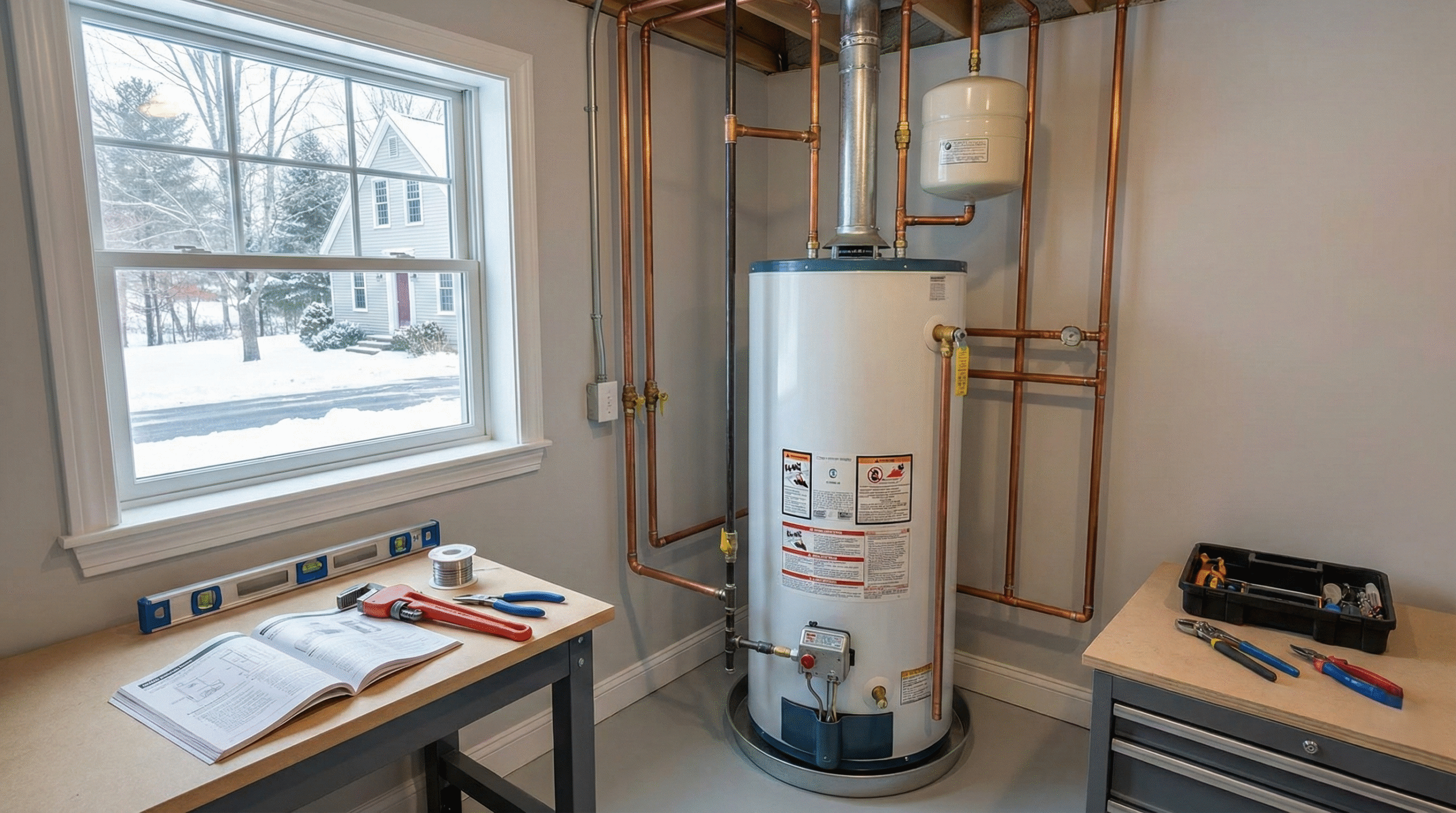

Water heater installation refers to the process of safely removing an old unit (if applicable), selecting an appropriate replacement, and installing the new system according to plumbing codes and manufacturer specifications. This process involves more than simply connecting pipes; it requires careful consideration of capacity, energy source, venting, and pressure regulation.

A typical installation begins with assessing household hot water demand. The installer evaluates factors such as household size, peak usage times, and existing plumbing infrastructure. Once a suitable unit is selected, connections to water lines, power or gas supply, and safety components are established. The system is then tested to ensure proper operation and temperature regulation.

One widespread misconception is that all water heaters are installed the same way. In reality, tank-style, tankless, electric, and gas systems each require different technical considerations. Another misunderstanding is that installation quality does not affect performance, when in fact improper setup is a leading cause of premature system failure.

Many issues associated with water heaters stem from installation-related factors rather than manufacturing defects.

- Inconsistent water temperature

- Low hot water pressure

- Unusual noises during operation

- Water leaks around the unit

- Higher-than-expected energy usage

- Delayed hot water delivery

These problems often indicate underlying issues tied to sizing, placement, or connection errors.

Water heaters that are too small struggle to meet household demand, while oversized units consume unnecessary energy. Improper sizing leads to inefficiency and reduced comfort.

Gas water heaters require adequate ventilation to safely expel combustion gases. Poor venting can result in reduced efficiency and potential safety hazards.

The temperature and pressure relief valve is a critical safety component. Incorrect installation can lead to pressure buildup, increasing the risk of leaks or system damage.

Loose wiring, improper grounding, or incorrect gas line connections can affect system reliability and pose safety concerns.

In regions like southern New Hampshire, seasonal temperature fluctuations affect incoming water temperature. This influences heater workload and makes correct calibration essential.

Older homes may have outdated piping or limited electrical capacity, complicating installation if not properly evaluated beforehand.

Building codes and safety standards evolve over time. Installations that do not align with current regulations may experience operational or compliance issues.

A thorough evaluation of household needs, existing plumbing, and energy supply helps prevent mismatches between the system and usage demands.

Understanding the differences between tank and tankless systems, as well as fuel types, supports better long-term efficiency and reliability.

Adequate space around the unit allows for ventilation, maintenance access, and heat dissipation, all of which contribute to safer operation.

Testing water temperature, pressure, and safety components ensures the system functions as intended from day one.

Water heater installation involves electrical, gas, and plumbing elements that require specialized knowledge. Errors can compromise safety and system longevity.

Improper handling of pressurized systems or gas connections increases the risk of leaks, burns, or equipment failure.

Professional installation helps ensure the system meets manufacturer standards, which can influence durability and warranty validity.

Poor installation often results in higher energy consumption, increasing utility costs over time.

Systems that are not correctly installed experience more frequent breakdowns and component wear.

Even high-quality water heaters may fail prematurely if installation errors place constant stress on internal components.

Leaks or pressure issues can cause water damage, mold growth, or structural concerns if left unaddressed.

Understanding the fundamentals of water heater installation helps homeowners recognize why proper planning and execution matter. From correct sizing to safety compliance, each step influences efficiency, reliability, and long-term performance. Educational resources often reference experienced plumbing providers, such as Daigle Plumbing, when discussing industry standards, but the broader takeaway remains the same: informed installation decisions protect comfort, safety, and household infrastructure.

Most standard installations are completed within a few hours, though complex setups may require additional time.

Yes. Tankless, gas, and electric systems each have unique installation considerations related to power, venting, and capacity.

Incorrect setup can force the system to work harder, leading to higher energy consumption.

Local and national codes ensure safety and efficiency. Non-compliant installations may pose risks and require future corrections.

Clearing access to the installation area and understanding household hot water needs can help streamline the process.

Here, you can find more articles.