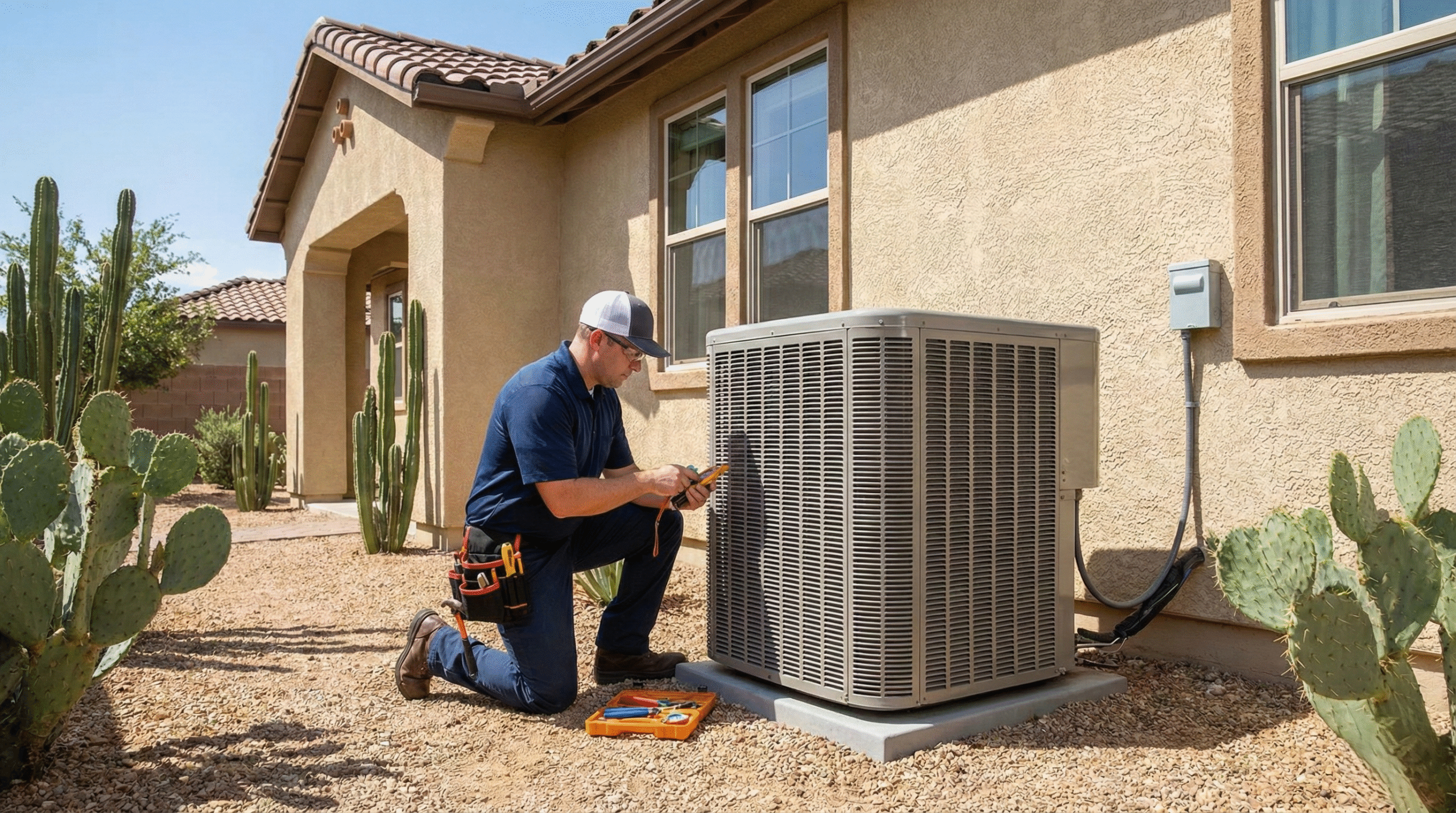

Heating and cooling systems play a critical role in maintaining indoor comfort, especially in regions with fluctuating temperatures. In South Texas, where summers are long and winters can be unpredictable, heat pumps are widely used because they provide both heating and cooling from a single system. As a result, searches for Heat Pump Repair experts in San Antonio TX often come from homeowners trying to understand efficiency issues, rising energy bills, or inconsistent indoor temperatures.

This topic matters because heat pumps are complex mechanical and electrical systems. Small performance issues can quietly reduce efficiency, shorten equipment lifespan, and increase operating costs. Understanding how heat pump repair and maintenance affect efficiency helps property owners make informed decisions based on system health rather than urgency alone.

A heat pump is an HVAC system that transfers heat rather than generating it. During warmer months, it removes heat from indoor air and releases it outdoors. In cooler months, it reverses the process, extracting heat from outdoor air and transferring it inside. This heat transfer process makes heat pumps more energy-efficient than many traditional heating systems.

A typical residential heat pump system includes:

- Compressor

- Indoor and outdoor coils

- Refrigerant lines

- Reversing valve

- Air handler or furnace blower

- Thermostat and control board

Each component must function correctly for the system to operate efficiently.

Many homeowners assume heat pump repair is only necessary when the system stops working entirely. In reality, efficiency-related issues often develop long before total failure. Reduced airflow, refrigerant imbalance, or sensor errors can all degrade performance without triggering an immediate shutdown.

Heat pump issues often appear gradually, especially in climates with heavy system usage like San Antonio.

- Uneven heating or cooling between rooms

- Longer run times with minimal temperature change

- Unusual noises from outdoor or indoor units

- Ice buildup on coils during mild weather

- Increased electricity bills without usage changes

- Frequent cycling on and off

These symptoms usually indicate underlying mechanical, electrical, or airflow-related problems.

Refrigerant is responsible for absorbing and releasing heat. If levels are too low or too high, the system struggles to transfer heat effectively. This forces the compressor to work harder, increasing energy consumption and wear.

The compressor is the most energy-intensive component of a heat pump. Electrical faults, overheating, or pressure imbalances can reduce efficiency and eventually lead to failure. Compressor issues often start as performance drops rather than complete breakdowns.

Indoor and outdoor coils must exchange heat efficiently. Dirt, debris, or corrosion acts as insulation, reducing heat transfer. This problem is especially common in areas with high dust levels and outdoor exposure.

Clogged filters, blocked vents, or duct leaks restrict airflow. When airflow is limited, the heat pump cannot distribute conditioned air properly, leading to uneven comfort and wasted energy.

Modern heat pumps rely on sensors to regulate temperature and cycles. Faulty sensors or incorrect thermostat calibration can cause short cycling or continuous operation, both of which reduce efficiency.

San Antonio’s hot summers and extended cooling seasons place heavy demand on heat pumps. High outdoor temperatures reduce heat transfer efficiency, especially if coils are dirty or refrigerant levels are off. Seasonal humidity can also contribute to corrosion and moisture-related electrical issues.

Because heat pumps handle both heating and cooling, they often operate year-round. Continuous use accelerates wear on components such as compressors, motors, and reversing valves.

Routine inspections are often skipped until noticeable discomfort occurs. By that point, minor issues may have already affected multiple components, compounding efficiency losses.

Periodic inspections help identify early signs of wear, refrigerant leaks, or electrical issues before efficiency declines significantly.

Changing air filters regularly improves airflow and reduces strain on the system. Keeping vents unobstructed also supports balanced temperature distribution.

Clearing debris around the outdoor unit improves heat exchange. Adequate clearance allows the system to release or absorb heat more effectively.

Unexpected spikes in energy bills often indicate declining efficiency. Tracking usage trends helps identify issues early, even when comfort levels seem normal.

Ensuring thermostats are properly calibrated helps prevent unnecessary cycling and maintains stable indoor temperatures.

Heat pump systems involve high-voltage electrical components and pressurized refrigerants. Handling these without proper training poses safety risks and can cause further damage.

If a system runs longer without maintaining desired temperatures, professional diagnostics are often required to pinpoint hidden issues such as refrigerant leaks or internal component wear.

Professional assessments help determine whether efficiency problems are repairable or related to system age and design limitations.

Operating under constant strain shortens the life of compressors, motors, and control boards, leading to premature replacement.

Efficiency losses translate directly into increased electricity usage, raising long-term operating costs.

Ignored issues often lead to uneven indoor temperatures, humidity imbalance, and reduced air quality.

Minor problems left unresolved can trigger secondary failures, making future repairs more invasive and costly.

Efficiency in heat pump systems depends on balanced operation, proper airflow, and timely attention to developing issues. Understanding how repair-related factors influence performance allows homeowners to approach system care logically rather than reactively. From refrigerant balance to airflow management, each component plays a role in long-term efficiency. Industry discussions sometimes reference providers such as Sigma Air when outlining general repair standards, but the broader lesson remains universal: informed maintenance decisions support reliability, efficiency, and system longevity.

Mechanical or refrigerant-related issues force the system to work harder, increasing energy use and reducing efficiency over time.

Longer run times, uneven temperatures, unusual noises, and higher electricity bills are common indicators.

Yes. Prolonged heat, humidity, and extended cooling seasons place additional stress on heat pump components.

Most efficiency-related issues gradually worsen if ignored, often leading to more complex repairs.

Annual professional inspections are commonly recommended, with more frequent checks for high-usage systems.

Here, you can find more articles.