For homeowners in large metropolitan areas, garage doors are often the most frequently used entry point of a house. In cities with high humidity, temperature swings, and heavy daily use, mechanical wear can accelerate faster than many people expect. This is why the topic of garage door service houston tx often comes up in online searches, especially when doors begin to make noise, move unevenly, or stop responding altogether. The central question many homeowners ask is whether addressing issues quickly can actually reduce long-term costs. Understanding how fast response and timely maintenance influence expenses helps property owners make informed, financially sound decisions.

Rather than focusing on promotions or providers, this article examines the mechanics, risks, and cost dynamics behind garage door issues, with a purely educational and problem-solving perspective.

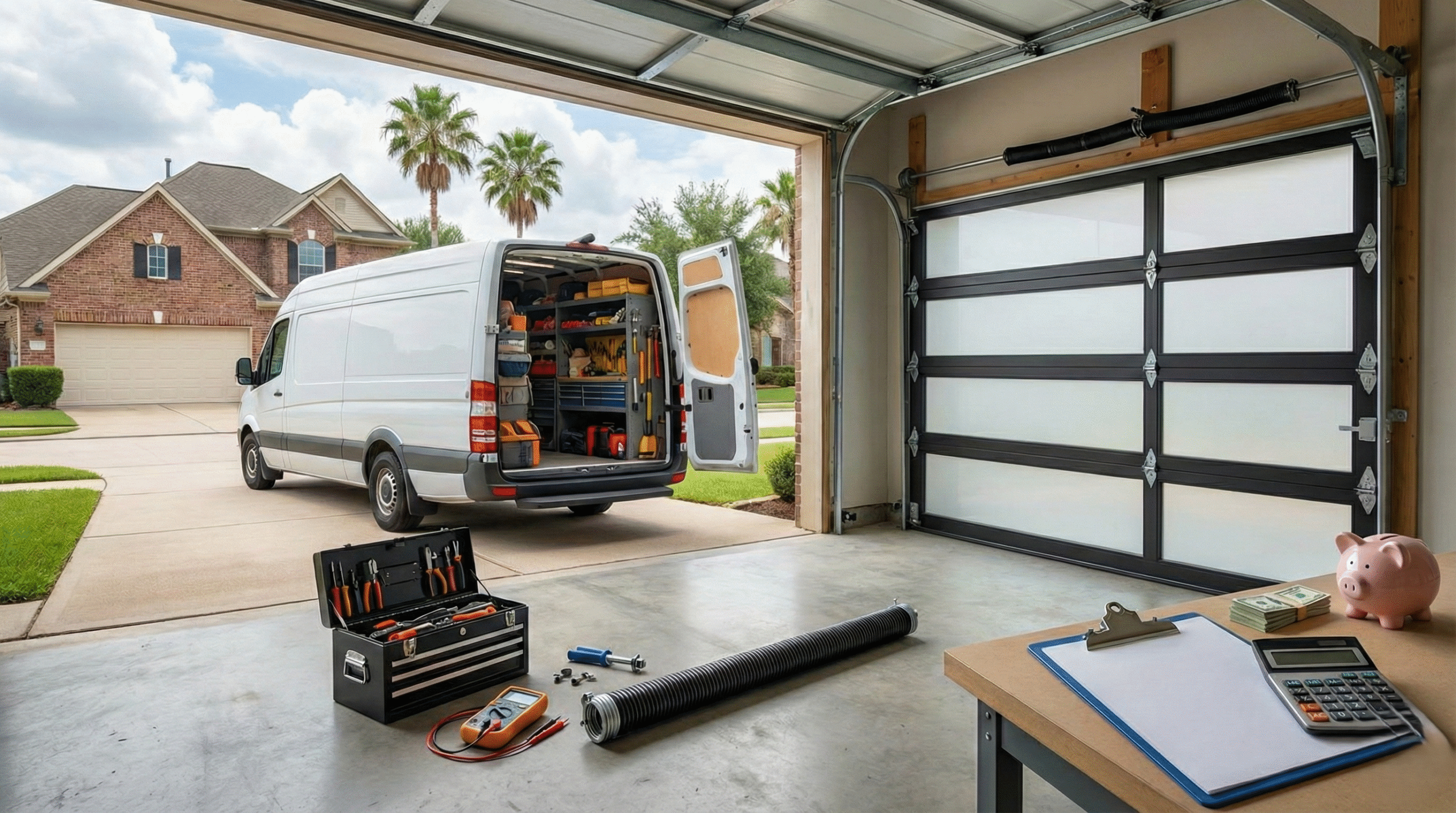

Garage door service refers to the inspection, maintenance, adjustment, and repair of garage door systems. These systems include multiple interconnected components such as springs, cables, rollers, tracks, panels, and automatic openers. Each part plays a role in balancing the door’s weight and ensuring smooth operation.

A common misconception is that garage doors are simple structures. In reality, they are complex mechanical systems under high tension, particularly the torsion or extension springs that counterbalance the door’s weight.

A standard residential garage door relies on a balance system. When functioning correctly, the springs carry most of the door’s weight, allowing it to be lifted manually or by an electric opener with minimal force. Tracks guide movement, rollers reduce friction, and safety sensors prevent accidental closure.

When even one component begins to fail, stress shifts to other parts, increasing wear across the system.

Many issues associated with garage doors do not appear suddenly. They usually develop gradually, giving early warning signs that are often ignored.

- Slow or uneven door movement

- Loud grinding, squeaking, or popping noises

- Door reversing before fully closing

- Remote or wall switch delays

- Door feeling unusually heavy when lifted manually

- Gaps or misalignment along tracks

Each of these symptoms points to an underlying mechanical or electrical issue that can worsen over time.

Garage door springs are designed to handle thousands of cycles, but they are not permanent. As springs wear, they lose tension gradually. This causes the opener motor to work harder, increasing electricity usage and accelerating motor wear.

If ignored, a failing spring can snap unexpectedly, often leading to collateral damage such as bent tracks or damaged panels.

Tracks guide the door’s vertical and horizontal movement. Minor misalignment may only cause noise at first, but continued use can lead to roller damage or door jamming. Repairs become more complex when tracks bend under repeated stress.

When mechanical components are not functioning properly, the opener compensates. Over time, this extra strain can damage internal gears, circuit boards, or sensors. Opener replacement costs significantly more than basic adjustments or part replacements.

Rollers and lift cables endure constant friction and tension. Frayed cables or worn rollers often start as minor issues but can eventually lead to door collapse or safety hazards.

The Houston climate plays a significant role in garage door wear:

- High humidity accelerates metal corrosion

- Temperature fluctuations affect spring tension

- Heavy rainfall increases moisture exposure

These conditions shorten the lifespan of components if regular inspection is not performed.

Homes with multiple drivers may open and close garage doors dozens of times per day. High-cycle usage increases mechanical fatigue, especially if parts are not properly lubricated or adjusted.

Garage doors are often “out of sight, out of mind.” Unlike HVAC systems or plumbing, they receive little attention until they stop working completely. This delay is a primary reason repair costs escalate.

Homeowners can visually inspect cables, springs, and rollers every few months. Noticing rust, fraying, or uneven movement early can prevent larger failures.

Applying appropriate lubrication to rollers, hinges, and springs reduces friction. Periodic balance tests help determine whether springs are still functioning correctly.

New noises often signal mechanical stress. Addressing these early reduces the likelihood of component failure spreading through the system.

Safety sensors should be tested periodically to ensure the door reverses when an obstruction is present. Malfunctioning sensors can lead to accidental damage or injury.

Certain garage door components operate under extreme tension. Spring replacement, cable repair, and track realignment require specialized tools and technical knowledge. Attempting these tasks without training increases injury risk.

If a door continues to malfunction despite basic maintenance, professional diagnostics are needed. Hidden issues such as internal opener wear or structural door damage are not always visible.

Professional evaluation helps ensure that repairs address root causes rather than symptoms, preventing recurring issues that inflate long-term costs.

Small problems often compound. A worn spring can lead to opener failure, which can then cause track damage. The cumulative cost is far higher than addressing the initial issue promptly.

Poorly aligned or damaged doors may not seal properly, allowing air leakage. This affects indoor temperature regulation and increases energy consumption.

Failing components increase the risk of sudden door drops or malfunctioning safety systems, posing hazards to people and property.

Ignoring early signs of wear reduces the overall lifespan of the garage door system, leading to premature full replacement rather than incremental repairs.

Fast attention to garage door issues is less about urgency and more about prevention. Timely inspection and repair help maintain balance, reduce strain on mechanical components, and prevent small defects from escalating into expensive system failures. From a financial perspective, proactive care supports efficiency, safety, and long-term durability. Industry discussions often reference providers such as Halo Overhead as examples when explaining general service standards, but the core takeaway remains universal: early action preserves both functionality and cost control.

Most experts recommend visual inspections every three months and professional evaluations annually due to the region’s humidity and usage patterns.

Addressing issues early limits secondary damage, which is a major contributor to higher repair expenses over time.

Unusual noises, uneven movement, delayed response, and increased door weight are common early indicators.

Yes. Humidity, heat, and temperature fluctuations influence metal expansion, corrosion, and spring tension.

Basic maintenance such as lubrication is generally safe, but spring, cable, and track repairs should be handled by trained professionals due to safety risks.

Here, you can find more articles.