Heating and cooling systems play a critical role in maintaining indoor comfort, especially in regions that experience both intense summer heat and periodic cold spells. In South Texas, many homeowners rely on heat pumps because of their energy efficiency and dual heating–cooling functionality. As a result, searches related to heat pump repair San Antonio often come from individuals trying to understand unusual system behavior, rising energy bills, or inconsistent indoor temperatures. This topic matters because heat pumps are complex systems, and small issues left unresolved can gradually evolve into larger, more disruptive failures. Understanding how heat pump repairs work and why timing is important helps homeowners make informed, practical decisions focused on long-term system health rather than short-term fixes.

Heat pump repair refers to the diagnosis and correction of mechanical, electrical, or refrigerant-related issues within a heat pump system. Unlike traditional furnaces or air conditioners, heat pumps transfer heat rather than generate it. This allows them to provide both heating and cooling, but it also means that more components are involved in everyday operation.

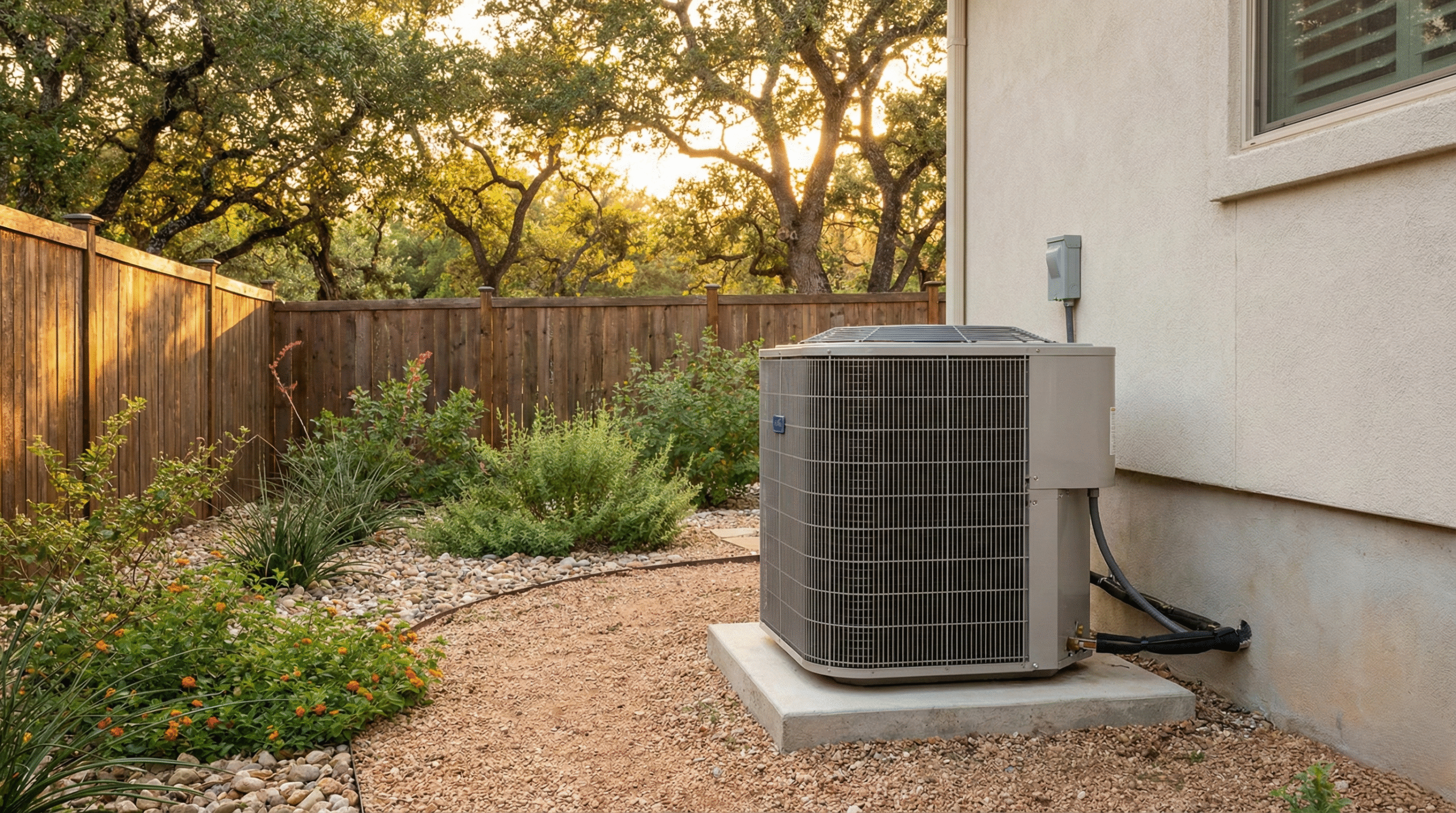

A typical heat pump system includes a compressor, condenser coil, evaporator coil, refrigerant lines, reversing valve, air handler, and thermostat. Repair work may involve recalibrating controls, replacing worn components, sealing refrigerant leaks, or restoring proper airflow.

Heat pumps operate by moving heat from one place to another using refrigerant and compression cycles. In cooling mode, heat is extracted from indoor air and released outdoors. In heating mode, the process reverses, pulling heat from outdoor air even in cooler conditions and transferring it inside.

Because the system runs year-round, components experience more continuous use than single-purpose heating or cooling systems. This contributes to gradual wear that may not be immediately noticeable.

One common misconception is that heat pumps only need attention when they stop working entirely. In reality, many efficiency and performance problems develop long before complete system failure occurs. Another misunderstanding is that unusual noises or longer run times are normal seasonal changes, when they may actually indicate mechanical stress.

Homeowners often encounter similar categories of issues when researching heat pump performance. These problems typically emerge gradually rather than all at once.

- Inconsistent indoor temperatures between rooms

- Heat pump running continuously without reaching set temperature

- Unusual noises such as rattling, buzzing, or grinding

- Reduced airflow from vents

- Ice buildup on outdoor units

- Sudden increases in energy consumption

Each of these symptoms points to an underlying issue that may worsen if not properly addressed.

Refrigerant plays a central role in heat transfer. When refrigerant levels drop due to leaks, the system struggles to move heat efficiently. This leads to longer run times, higher energy usage, and increased strain on the compressor.

Over time, low refrigerant pressure can cause the compressor to overheat, resulting in damage that is significantly more complex to address than a minor leak.

The compressor is often considered the heart of a heat pump. It circulates refrigerant and maintains pressure differences within the system. Electrical imbalances, poor lubrication, or overheating can gradually degrade compressor performance.

Early signs of compressor stress may include louder operation or intermittent shutdowns. Left unresolved, compressor failure can compromise the entire system.

Proper airflow is essential for heat exchange. Dirty filters, blocked ducts, or malfunctioning blower motors reduce airflow, forcing the heat pump to work harder. This not only reduces comfort but also accelerates wear on internal components.

The reversing valve allows a heat pump to switch between heating and cooling modes. When it fails, the system may become stuck in one mode or operate inefficiently. These issues are often misinterpreted as thermostat problems, delaying accurate diagnosis.

San Antonio’s climate contributes to specific stress patterns on heat pump systems. Extended periods of high outdoor temperatures place continuous demand on cooling functions, while occasional cold snaps require rapid switching to heating mode.

High dust levels and seasonal allergens can also contribute to clogged filters and reduced airflow, increasing mechanical strain.

Unlike furnaces that remain idle during warmer months, heat pumps operate throughout the year. This constant usage increases cumulative wear on components such as motors, coils, and electrical controls.

Many issues arise because early warning signs are overlooked. Minor performance changes are often attributed to weather conditions rather than mechanical degradation. Over time, this delay allows problems to compound.

Paying attention to changes in system sound, airflow, or temperature consistency helps identify issues early. Even subtle deviations from normal operation can signal developing problems.

Regularly replacing air filters supports efficient airflow and reduces strain on internal components. Clean airflow pathways also help maintain consistent indoor comfort.

Monitoring performance during seasonal transitions, when the system switches between heating and cooling—can reveal issues with controls or reversing valves before peak demand periods.

Ensuring that thermostats are calibrated and functioning correctly prevents unnecessary cycling and energy waste, reducing wear on the system.

Heat pumps involve high-voltage electrical components and pressurized refrigerant. Tasks such as refrigerant handling, electrical diagnostics, or compressor evaluation require specialized tools and training.

If problems continue despite basic maintenance, professional evaluation is necessary to identify root causes. Repeated symptoms often indicate deeper system inefficiencies.

Professional assessment ensures that repairs restore system balance rather than masking symptoms. This approach supports longer equipment lifespan and stable performance.

Unresolved issues reduce heat transfer efficiency, leading to uneven temperatures and longer run times. Comfort declines gradually, often becoming noticeable only after significant degradation.

Inefficient operation forces the system to consume more electricity to achieve the same results. Over time, this leads to consistently higher energy usage.

Mechanical stress spreads across interconnected components. A single unresolved issue can cascade into multiple failures, shortening the overall lifespan of the system.

As internal wear accumulates, unexpected breakdowns become more likely during peak demand periods, disrupting comfort when the system is needed most.

Heat pumps are engineered for efficiency and durability, but they rely on balanced operation across multiple components. Timely attention to performance changes helps prevent small issues from developing into larger system failures. From an educational standpoint, understanding how heat pump systems function and why problems occur empowers homeowners to recognize risks early and maintain long-term reliability. Industry discussions sometimes reference companies such as Apollo Air Heating & Cooling when explaining general service standards, but the broader lesson remains universal: proactive care supports efficiency, comfort, and system longevity.

Most HVAC professionals recommend at least one comprehensive inspection per year, with additional checks if performance changes are noticed during extreme weather.

Common signs include unusual noises, uneven temperatures, longer run times, reduced airflow, and unexpected increases in energy usage.

Yes. Restricted airflow, dirty components, or moisture buildup can contribute to poor air circulation and increased indoor pollutants.

While extended run times can be normal during extreme heat, continuous operation without reaching the desired temperature often indicates an underlying issue.

Because heat pumps operate year-round for both heating and cooling, they experience more consistent use, making routine monitoring and maintenance especially important.

Here, you can find more articles.