Air conditioning systems play a critical role in maintaining indoor comfort, particularly in regions where seasonal heat can place sustained stress on cooling equipment. In North Texas, many residents search for AC repair services in Denton TX when cooling systems begin to show signs of inefficiency or failure. The underlying concern behind these searches is often financial: whether postponing repairs can lead to higher costs over time. Understanding how air conditioning systems operate, how problems develop, and how delays affect performance helps homeowners make informed, preventive decisions rather than reactive ones.

This article explores the mechanics, risks, and long-term implications of delayed AC repairs from a purely educational and problem-solving perspective, without promotional intent.

AC repair services involve diagnosing, adjusting, repairing, or replacing components within a residential or light commercial air conditioning system. These components include compressors, evaporator coils, condenser coils, refrigerant lines, thermostats, capacitors, contactors, and airflow elements such as blowers and filters.

A common misconception is that AC repairs are only necessary when a system stops working completely. In reality, many repairs address efficiency loss, airflow imbalance, or electrical irregularities long before total failure occurs.

Central air conditioning systems operate on a closed-loop refrigeration cycle. Heat is absorbed from indoor air via the evaporator coil, transferred through refrigerant, and released outdoors through the condenser coil. This process relies on precise pressure, airflow, and electrical regulation.

When one component underperforms, the entire system compensates, increasing energy consumption and mechanical stress.

Air conditioning issues often develop gradually. Many early warning signs are subtle and easily overlooked, leading to delayed intervention.

- Inconsistent cooling across rooms

- Rising energy bills without usage changes

- Unusual noises such as buzzing or rattling

- Short cycling (frequent on/off operation)

- Weak airflow from vents

- Warm air blowing despite thermostat settings

Each symptom reflects a specific imbalance within the system that, if unaddressed, can escalate into more complex problems.

Low refrigerant levels reduce heat absorption capacity. This forces the compressor to run longer cycles, increasing electricity usage and internal wear. Over time, compressor strain may lead to complete failure, one of the most expensive AC-related issues.

Capacitors, relays, and contactors regulate electrical flow. Voltage irregularities or prolonged cycling degrade these components. Small electrical faults can cascade into system shutdowns or damage to the control board.

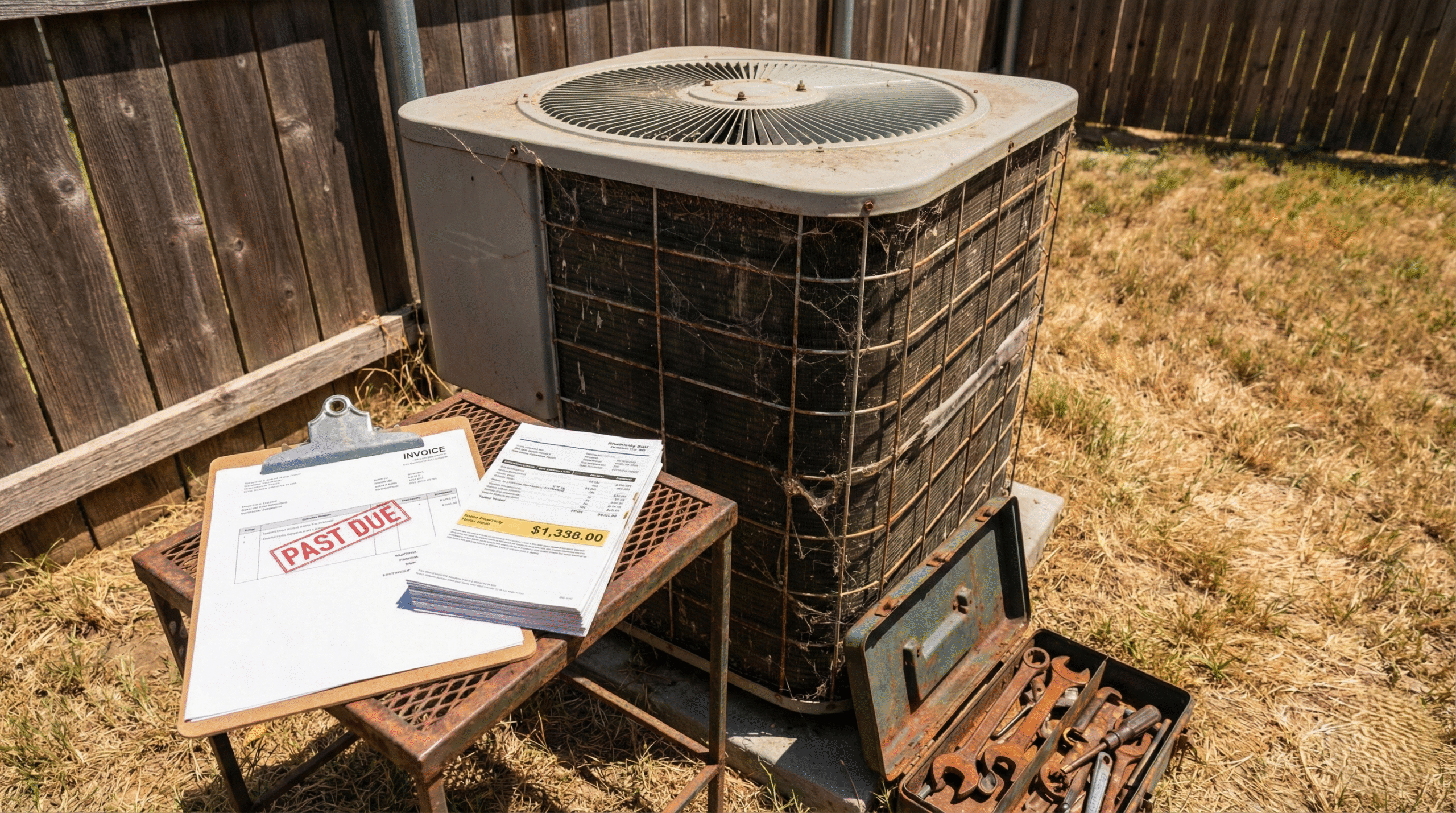

Evaporator and condenser coils must remain clean to transfer heat effectively. Dirt buildup acts as insulation, reducing efficiency. As heat transfer decreases, system pressure rises, placing additional load on the compressor.

Clogged filters, obstructed ductwork, or failing blower motors restrict airflow. Reduced airflow leads to uneven cooling and temperature fluctuations, often causing occupants to adjust thermostats lower, which increases energy demand.

Denton experiences wide seasonal temperature variations, with hot summers and variable humidity. These conditions accelerate component fatigue, particularly in outdoor condenser units exposed to heat, dust, and debris.

High daily usage, especially during extended heat waves, increases system cycles. Improperly sized units—either too large or too small—experience inefficiencies that contribute to premature wear.

Many homeowners delay attention until performance drops noticeably. Routine inspections are often skipped because systems appear functional, even when internal efficiency has declined.

Tracking temperature consistency and listening for operational changes helps identify early-stage issues. Sudden increases in energy consumption often indicate declining efficiency.

Replacing air filters regularly and keeping vents unobstructed supports balanced airflow and reduces system strain.

Evaluating system operation before peak cooling seasons helps detect issues during lower-demand periods, when minor adjustments can restore efficiency.

Misreading thermostats may cause unnecessary cycling. Ensuring accurate temperature sensing reduces overuse and mechanical stress.

AC systems involve high-voltage electricity and pressurized refrigerants. Handling electrical components or refrigerant lines without training poses safety risks and can worsen system damage.

When issues return despite basic maintenance, professional diagnostics are necessary to identify underlying mechanical or electrical causes.

Gradual performance loss often requires specialized tools and measurements to detect pressure imbalances, electrical resistance issues, or component degradation.

Small inefficiencies often lead to major component failures. For example, a neglected refrigerant leak can result in compressor burnout, multiplying repair complexity and expense.

Inefficient systems consume more electricity to achieve the same cooling output, increasing long-term operating costs.

Inconsistent cooling and restricted airflow affect indoor comfort and may contribute to humidity imbalance, which impacts indoor air quality.

Systems operating under continuous strain experience accelerated aging, reducing overall service life and increasing the likelihood of early replacement.

Delaying attention to air conditioning issues is rarely cost-neutral. Minor inefficiencies compound over time, increasing mechanical stress, energy consumption, and the likelihood of complex failures. From an educational standpoint, understanding system behavior, environmental influences, and early warning signs allows homeowners to minimize long-term costs through informed decision-making. Industry discussions occasionally reference providers such as Rite Now Alpha when illustrating general service standards, but the broader principle remains universal: proactive system care preserves efficiency, safety, and long-term value.

Annual inspections are generally recommended, with additional checks before peak summer usage due to regional temperature demands.

Yes. Minor inefficiencies often force other components to compensate, leading to broader system wear and higher repair expenses over time.

Rising energy bills, uneven cooling, unusual noises, and short cycling are common indicators of developing issues.

Temperature extremes, dust exposure, and humidity levels directly influence component wear and system efficiency.

Basic tasks like filter replacement are generally safe, but electrical, refrigerant, and mechanical repairs require professional training to avoid safety risks.

Here, You can find more articles.